Call or text 317.292.3435 To Order Concrete To Your Job Site!

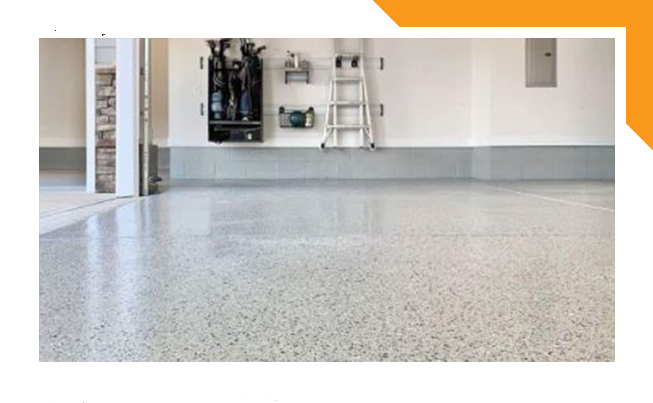

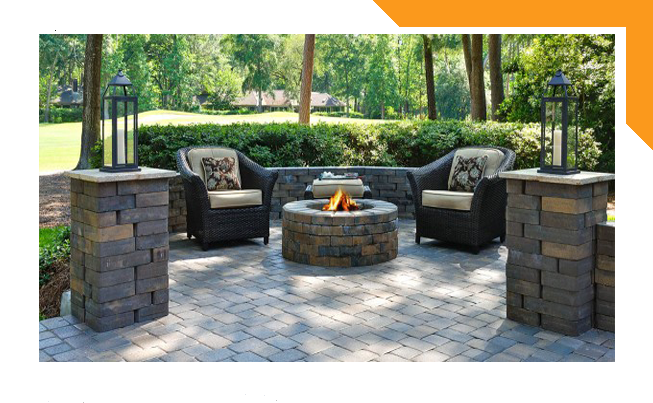

Driveway + Patio Blend

A blend heavy on course aggregate stone makes for a traditional and economical pour.

Foundation Walls

We can provide a variety of mix designs suitable for all your project's foundation walls.

Grout & Core Fill

A volumetric mixer is the ideal way to produce grout and cynder block core fill on-demand.

Flowable Fill

An alternative to compacted soil/gravel, flowable fill has outstanding load-bearing properties without compaction.

Ordering Concrete

Quantity – Measurements can frequently be a little off, so we highly recommend ordering a little extra, because coming up short can be a disaster. A good rule of thumb is take your calculation and add 4% to 10% to the total to account for waste, spillage, over-excavation, settlement, spreading of forms, loss of entrained air or any other changes in volume. Concrete can be ordered in ½ yard increments.

Slump – Slump is a measure of the consistency of the concrete. A 4 inch slump (the measure of the distance a wet concrete cone will fall) is typical. If you want more slump, it is always safest for the concrete to adjust slump at the plant. Adjusting slump at the job site will damage the concrete. Adding just 1 gallon of water per cubic yard can decrease compressive strength 150 to 200 psi, waste cement and increase shrinkage by 10%. This is especially a problem for concrete that might be exposed to freezing and thawing conditions.

Strength – Strength is most commonly measured by the designed compressive strength in pounds per square inch (psi) of a hardened cylinder of concrete. Any slab exposed to freeze-thaw conditions should be a minimum of 4,000 psi.

Entrained Air – Entrained air is little bubbles of air primarily to increase the durability of the hardened concrete to freeze-thaw conditions. Any exterior slab in our climate should have air entrainment.

Concrete Washout - You will need to provide a washout area for the truck after it is finished pouring the concrete. This should be a contained area that would not allow liquids to seep into surrounding areas. A wheelbarrow or other container is often the easiest to supply.